Off-Delay, On-Delay Time Delay Relay: Working, Use Cases, and Benefits

In industrial automation and electronic control systems, timing plays a critical role in ensuring efficient operation. This is where Off-Delay and On-Delay Time Delay Relays come into action. These relays are essential components in electronics that help manage delayed switching based on a preset time, enhancing control, safety, and system precision.

This article explains how Off-Delay and On-Delay Time Delay Relays function, their differences, applications, and why they are indispensable in modern control systems like controllers, sensors, and microprocessors.

Understanding the Basics of Time Delay Relays

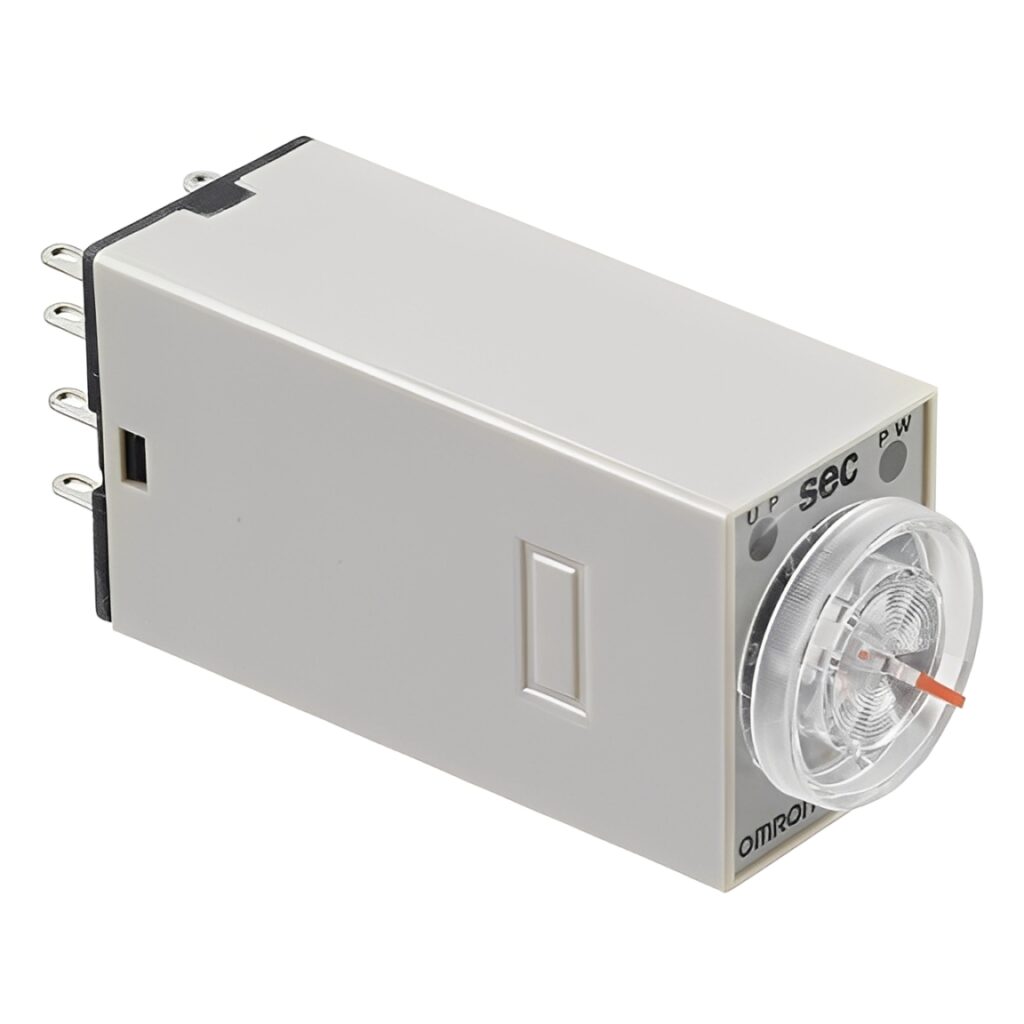

A time delay relay is a type of electromechanical or solid-state switch designed to activate or deactivate after a specified time delay. It provides logical control to circuits that need a delay in operation.

The two most common types include:

- On-Delay Relay: Delays the turning ON of a load.

- Off-Delay Relay: Delays the turning OFF of a load.

These relays work with various components, including switches, capacitors, sensors, connectors, and controllers, providing crucial timing control.

What Is an On-Delay Time Delay Relay?

An On-Delay Time Delay Relay is configured so that when the input voltage is applied, there is a delay before the relay contacts change state. This delay is predefined and can be adjusted.

Applications of On-Delay Relays

- Conveyor systems to prevent simultaneous motor starts.

- Heating circuits to avoid thermal overshoots.

- Industrial electronics where process sequencing is vital.

- Capacitor charge control in controllers and microcontrollers.

Key Benefits

- Reduces electrical and mechanical stress on circuits.

- Improves energy management and system longevity.

- Provides controlled activation of devices like fans, fuses, and LED systems.

What Is an Off-Delay Time Delay Relay?

An Off-Delay Time Delay Relay operates inversely. It energizes the load instantly when input power is applied. When the power is removed, the relay contacts stay in their energized state for a set period before returning.

Applications of Off-Delay Relays

- Safety lighting systems that remain on after switching off.

- Industrial fans that continue running to cool components.

- Door mechanisms in access control systems using sensors.

- Machine shutdown sequences in thermal-sensitive electronics.

Key Benefits

- Ensures system components shut down safely.

- Enhances post-operation cooling and protection.

- Reduces system wear and protects thermal elements, such as pads and oils.

Core Differences Between Off-Delay and On-Delay Relays

| Feature | On-Delay Relay | Off-Delay Relay |

|---|---|---|

| Activation Timing | Delay before turning ON | Delay before turning OFF |

| Input Requirement | Applies delay when input is ON | Applies delay when input is OFF |

| Control Logic | Prevents premature energizing | Prevents premature de-energizing |

| Common Uses | Conveyor belts, motors | Fans, alarms, lights |

Each is used with contactors, grips, tools, and fuses to ensure reliability and protection in critical applications.

Where Are Time Delay Relays Used?

Off-Delay and On-Delay Time Delay Relays are widely used across sectors:

Electronics & Automation

- Sequence control in controllers and microcontrollers.

- Delayed activation in laptops and industrial PCs.

- Prevent overheating of components using thermal sensors and relays.

Power & Safety Systems

- Overload protection using thermal pads and oils.

- Circuit protection with fuses and connectors.

- Alarm circuits that allow safe time for operator intervention.

Manufacturing and Industrial Equipment

- Switches and actuators requiring precise timing.

- Control of LED lights, motors, and pumps.

- Delayed motor shutdowns for safety in tools and heavy machinery.

Choosing the Right Time Delay Relay

When selecting a relay for your application, consider the following:

- Timing range: Based on the control system’s delay needs.

- Contact configuration: Choose NO or NC contacts based on load behavior.

- Voltage rating: Ensure compatibility with the control circuit.

- Environment: Consider thermal, dust, or moisture exposure.

Reliable connectors, cables, and accessories play a vital role in ensuring stable relay performance across industrial environments.

Integration With Electronic Systems

Modern Off-Delay and On-Delay relays can be easily integrated with:

- Sensors for automated feedback.

- Microprocessors for logical control in embedded systems.

- Controllers for operational automation in smart factories.

- Capacitors to control surge and delay timing accurately.

These integrations make the system more intelligent and reduce reliance on manual operation.

Final Thoughts

Off-Delay and On-Delay Time Delay Relays are fundamental in delivering operational efficiency, precision, and protection in a wide range of systems. From controlling thermal dynamics in electronics to managing actuator timing in automated environments, these relays support consistent performance and enhanced safety.

Their compatibility with sensors, switches, thermal accessories, and controllers makes them an essential component across industries focused on safety, automation, and control logic.

By understanding how these relays function and where they apply, industries can make informed choices to enhance workflow, prevent failures, and optimize equipment performance.