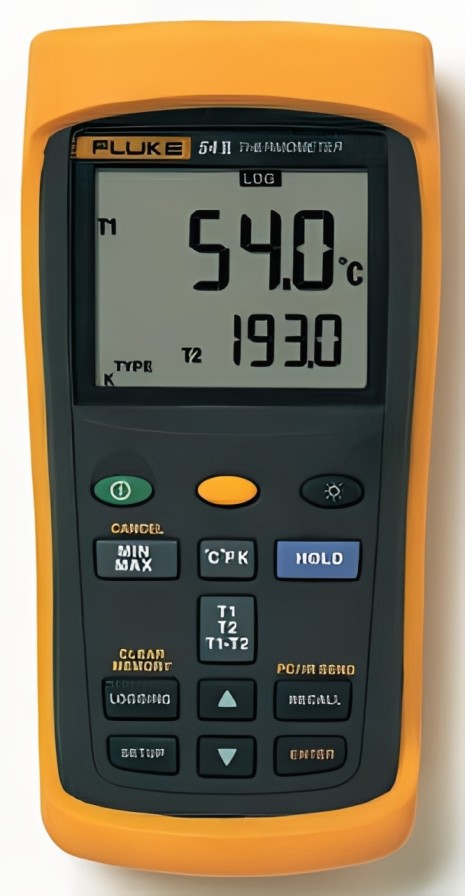

Why Choose a Fluke Handheld Digital Thermometer?

A Fluke Handheld Digital Thermometer is built for professionals who need dependable temperature readings during installation, troubleshooting, and preventive maintenance. Whether you are checking overheating contactors, validating process heat, or confirming safe operating limits, this compact tool helps you act quickly and confidently. Because temperature often reveals problems before failure, a quality handheld meter becomes a practical part of daily safety routines.

What a handheld thermometer does in real jobs

Temperature measurement is not only for laboratories. In field work, it supports fast decisions that protect uptime and people. A handheld thermometer can help you confirm whether a surface is stable, trending upward, or operating outside spec.

Common applications include:

- Verifying motor housings and control panels for abnormal thermal rise

- Checking heat sinks and thermal pads on electronics assemblies

- Validating HVAC supply and return temperatures

- Confirming process line temperatures in maintenance windows

Where it fits among electrical and maintenance tools

A handheld thermometer complements multimeters and clamp meters by adding context to electrical measurements. For example, a normal current reading does not always mean a healthy connection. However, if a connector, fuse, or switch body is hotter than surrounding points, you may have resistance, looseness, or contamination.

In a typical kit, the thermometer sits alongside:

- Basic safety tools and insulated grips for safer access

- Test cables and leads used for electrical checks

- Spare fuses and common switches for quick repairs

Key features to look for in a Fluke handheld thermometer

When you choose a professional instrument, focus on performance that improves repeatability and reduces errors in the field. While models differ, many Fluke handheld options share practical design goals.

Accuracy and response

In maintenance, accuracy matters, but so does a steady reading. Fast response is also important when temperatures change quickly or when you have limited access time near energized equipment.

Look for capabilities such as:

- Clear accuracy specifications across the working range

- Stable readings with common probes and sensors

- A response that supports quick spot checks and validation

Durable build for industrial environments

Field conditions include dust, temperature swings, and occasional drops. A rugged housing and a readable display support safer work, especially in panel rooms and plant spaces where lighting is not ideal.

Probe and sensor flexibility

Different tasks need different sensors. Contact measurements may use surface or immersion probes, depending on the material and access. In addition, many applications require probes that handle moisture and exposure to oils.

Practical probe considerations include:

- Compatibility with common thermocouple sensors

- A secure connector that resists pullout

- Cable routing that avoids pinch points and sharp edges

How temperature data improves troubleshooting

Temperature tells a story about energy loss and stress. When a component heats up, it is often a sign of inefficiency, friction, or excessive electrical resistance. As a result, temperature checks can help you narrow the problem faster.

Electrical panels and control components

Overheating in control panels can come from loose terminations, aging contactors, or overloaded circuits. A handheld thermometer lets you compare similar points under load, then target the root cause.

Examples of temperature driven checks include:

- Comparing adjacent breakers and fuse clips for uneven heating

- Checking connector blocks and terminal strips after torque verification

- Spotting hot switch contacts that indicate wear or arcing

Electronics and embedded systems

In electronics service, localized heat can indicate failing capacitors, stressed LEDs, or overloaded regulators. Temperature checks help when visual inspection is not enough, especially in compact enclosures.

Useful targets include:

- Capacitor bodies that run hotter than expected

- Microcontrollers and controllers that warm up under abnormal load

- Microprocessors in laptops that show thermal throttling symptoms

Mechanical systems and lubrication

Heat can also reveal friction, misalignment, or poor lubrication. If temperatures rise after start up, you may need to check alignment, belt tension, or bearing condition, then correct the cause before damage spreads.

Best practices for accurate field measurements

Even a high quality instrument benefits from good technique. Consistent methods reduce false alarms and improve confidence in maintenance decisions.

Create a repeatable routine

Choose reference points you can access every time, and measure under similar operating conditions. Then, record readings so you can compare trends instead of relying on memory.

A simple routine can include:

- Measure at steady state for consistent comparisons

- Compare left and right sides on similar equipment

- Log ambient temperature and airflow changes near the test point

Protect sensors and cables on the job

Probes and cables take the most abuse. Avoid tight bends, keep cables away from hot surfaces, and store sensors so tips are not crushed. If you work around rotating equipment, route cables securely and keep hands clear to maintain safety.

Integrating temperature checks into preventive maintenance

Temperature data becomes more valuable when it is part of a program. Instead of only measuring after a fault, use periodic checks to catch early warning signs.

High value inspection points include:

- Electrical cabinets during peak load periods

- Motor terminals and junction boxes

- Power supplies feeding critical controllers and drives

Conclusion

A Fluke Handheld Digital Thermometer supports faster decisions by turning heat into usable information. From electrical panels to electronics assemblies, it helps identify abnormal thermal patterns, verify repairs, and strengthen preventive maintenance routines. When you choose a durable instrument and follow consistent measurement practices, you gain a simple workflow that improves safety, protects equipment, and keeps operations running smoothly.