Why choose a JKL LED Cable for LED systems?

A JKL LED Cable is engineered to deliver stable power and signal to LEDs in demanding electronics. It pairs high-quality conductors with reliable insulation and connectors to protect circuits against noise, heat, and vibration. When correctly specified, the JKL LED Cable reduces loss, supports safety, and streamlines installation across signage, industrial controls, and architectural lighting.

What does a JKL LED Cable do in electronics?

The cable links drivers or controllers to LEDs, maintaining consistent current while minimizing voltage drop. In practice, it preserves brightness uniformity, protects sensitive components like a capacitor on an LED board, and ensures switches and sensors operate predictably.

- Carries DC power and low-voltage control for microcontrollers and controllers

- Shields against electrical noise from contactors, motors, and fuses

- Maintains integrity in compact enclosures with thermal constraints

How is the cable constructed for durability?

JKL LED Cables typically combine finely stranded copper with flexible insulation and, when needed, foil or braid shielding. This mix supports tight routing around heatsinks and thermal pads while resisting oils and abrasives common in industrial spaces.

- Stranded copper for flexibility and strong grips in connectors

- PVC, XLPE, or silicone insulation matched to expected thermal exposure

- Optional shielding to reduce EMI in control panels with microprocessors

- Outer jacket rated for oils, UV, and abrasion to extend service life

Which electrical properties should you evaluate?

Selecting the right JKL LED Cable starts with matching electrical characteristics to your LEDs and driver. Focus on conductor size, run length, and environmental factors.

- Conductor size: choose AWG that limits voltage drop to maintain LED brightness

- Temperature rating: verify continuous and peak thermal limits near heatsinks

- Dielectric strength: ensure insulation withstands the driver’s maximum output

- Shielding: specify where sensors or data lines run near noisy contactors

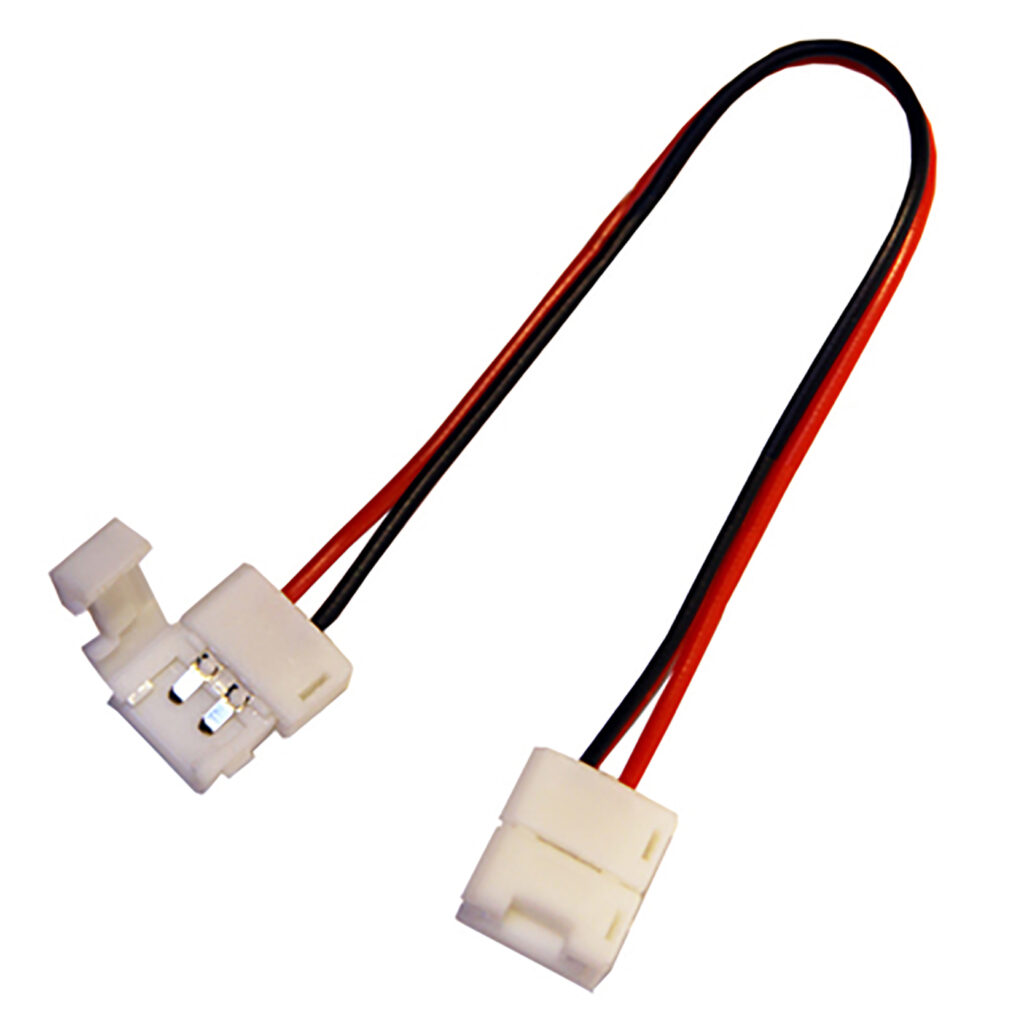

Are the connectors and terminations critical?

Yes. Even the best cable underperforms with weak terminations. Quality connectors reduce resistance, improve safety, and speed assembly on site.

- Use locking connectors to prevent intermittent faults from vibration

- Match pinouts to switches, drivers, and microcontrollers to avoid polarity errors

- Consider pre-terminated options for repeatable results and faster builds

- Verify strain relief so cables do not pull at solder joints on LEDs

How does installation affect safety and performance?

Good installation practice prevents hotspots, noise, and early failures. Route the JKL LED Cable with attention to bend radius and separation from high-power lines.

- Keep low-voltage LED cables away from mains conductors and contactors

- Follow bend radius guidance to protect conductors and insulation

- Use grommets and cable grips to relieve strain at panel entries

- Label polarity and channels to simplify maintenance and safety checks

Where is a JKL LED Cable commonly used?

Because it balances flexibility and robustness, you will find it across many sectors of electronics.

- Retail signage and architectural LEDs with long cable runs

- Industrial controls where sensors and controllers sit near drives

- Transportation lighting with vibration and oils in the environment

- Consumer devices and laptops where compact routing is essential

How do thermal considerations influence choice?

LED efficiency depends on temperature. Cable material and routing should support overall system thermal design.

- Choose insulation rated for the enclosure’s ambient and hotspot zones

- Keep cables clear of heatsinks and thermal pads to avoid heat soak

- Use jackets resistant to oils that can soften insulation at high temperatures

- Verify bundle sizes so trapped heat does not degrade the jacket

What selection checklist should you follow?

Use this quick framework to choose the right JKL LED Cable for LEDs, controllers, and microcontrollers.

- Electrical: voltage, current, run length, acceptable voltage drop

- Mechanical: bend radius, flexibility, abrasion, and routing constraints

- Environmental: thermal rating, oils, UV, and moisture exposure

- Interface: connector type, pin count, locking needs, and strain relief

- Compliance: flame class, low smoke rating, and regional approvals

How do you minimize voltage drop with longer cables?

Longer runs increase resistance, which dims LEDs and can destabilize sensors. Plan conductor size and topology early.

- Upsize the conductor to keep voltage at the LED within tolerance

- Shorten return paths and avoid unnecessary splices or switches

- Use distributed power injection in large arrays of LEDs

- Measure loaded voltage at the farthest point, not only at the driver

Which standards and approvals matter?

Compliance helps ensure safety and reliability, especially in commercial projects with fuses and contactors upstream.

- Look for recognized flame ratings appropriate to the installation site

- Confirm low-smoke, halogen-free options for enclosed public spaces

- Verify marking and traceability for audit and maintenance records

What maintenance practices extend service life?

Regular checks keep installations efficient and safe over time.

- Inspect connectors for looseness and discoloration from heat

- Confirm cable grips remain tight around entries and panels

- Clean dust and oils that can degrade jackets and retain heat

- Log revisions when rerouting to avoid hidden cross-coupling near sensors

How do you troubleshoot performance issues quickly?

If LEDs flicker or sensors misread, the cable path is a prime suspect.

- Check polarity and continuity from driver to LEDs and switches

- Measure voltage under load at the LED boards and controller terminals

- Inspect for nicks, crushed jackets, or over-tight ties causing conductor damage

- Evaluate EMI by separating cables from contactors and high-current lines

What trends are shaping future JKL LED Cable designs?

Emerging systems blend data and power while demanding smaller footprints.

- Hybrid power-plus-signal cables for addressable LEDs and smart controllers

- Materials tuned for higher thermal margins in compact fixtures

- Enhanced shielding for dense control cabinets with microprocessors

- Faster, tool-less connectors designed for repeatable field terminations

Key takeaways for specifying a JKL LED Cable

Choosing the right JKL LED Cable improves brightness consistency, reduces service calls, and supports safer, cleaner installations.

- Match conductor size to current, length, and acceptable drop

- Select insulation and jackets for thermal, oils, and abrasion exposure

- Use secure connectors with proper strain relief and labeling

- Route thoughtfully to separate low-voltage lines from noisy equipment

By aligning electrical, mechanical, and environmental needs, a JKL LED Cable becomes the reliable backbone of modern LED systems. With the right specification, installers deliver stable light output, responsive sensors, and long-term safety for electronics in retail, industrial, and commercial settings.